![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_PowerSplit_1250_Header_0605d09b04.png)

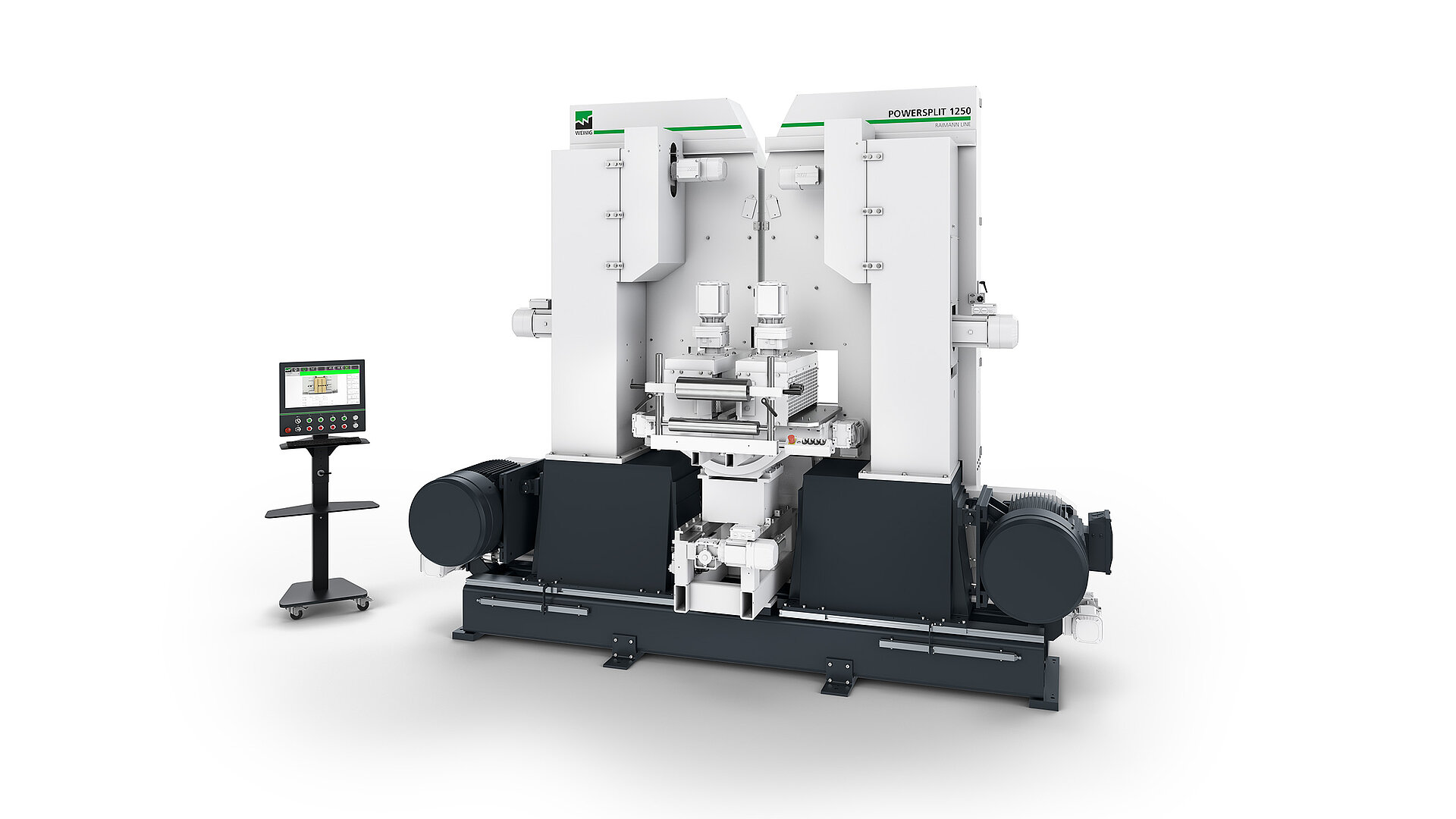

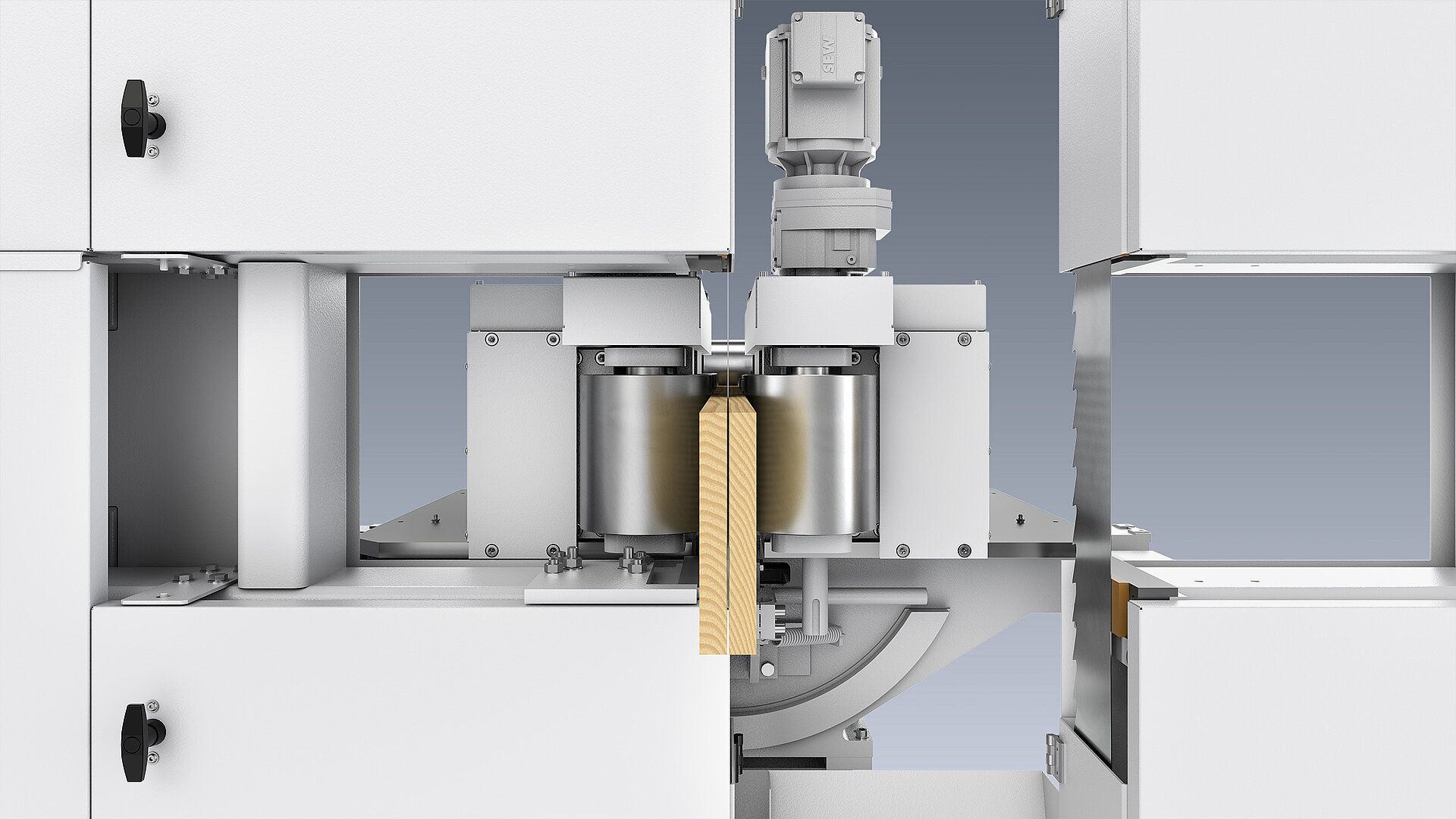

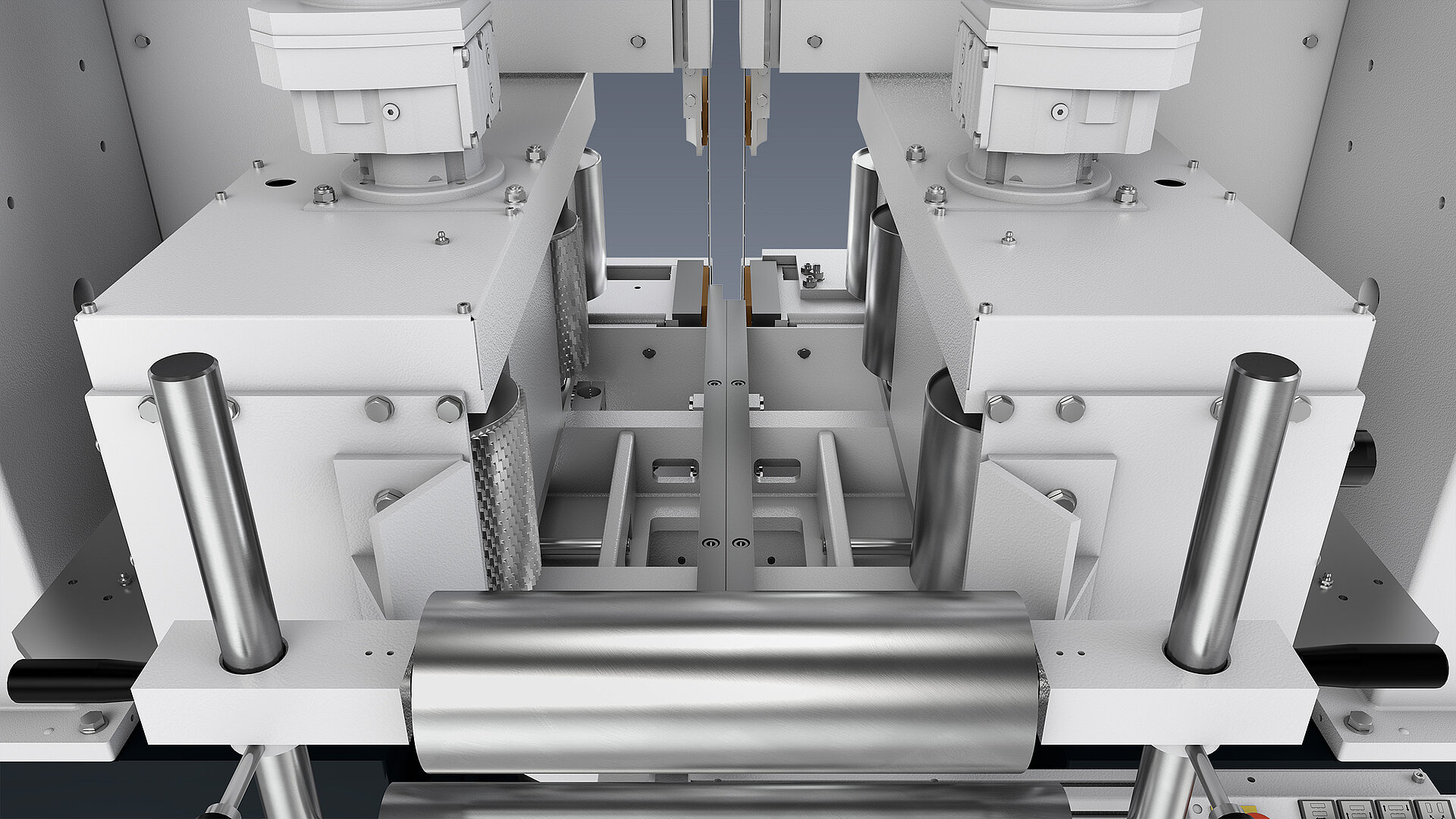

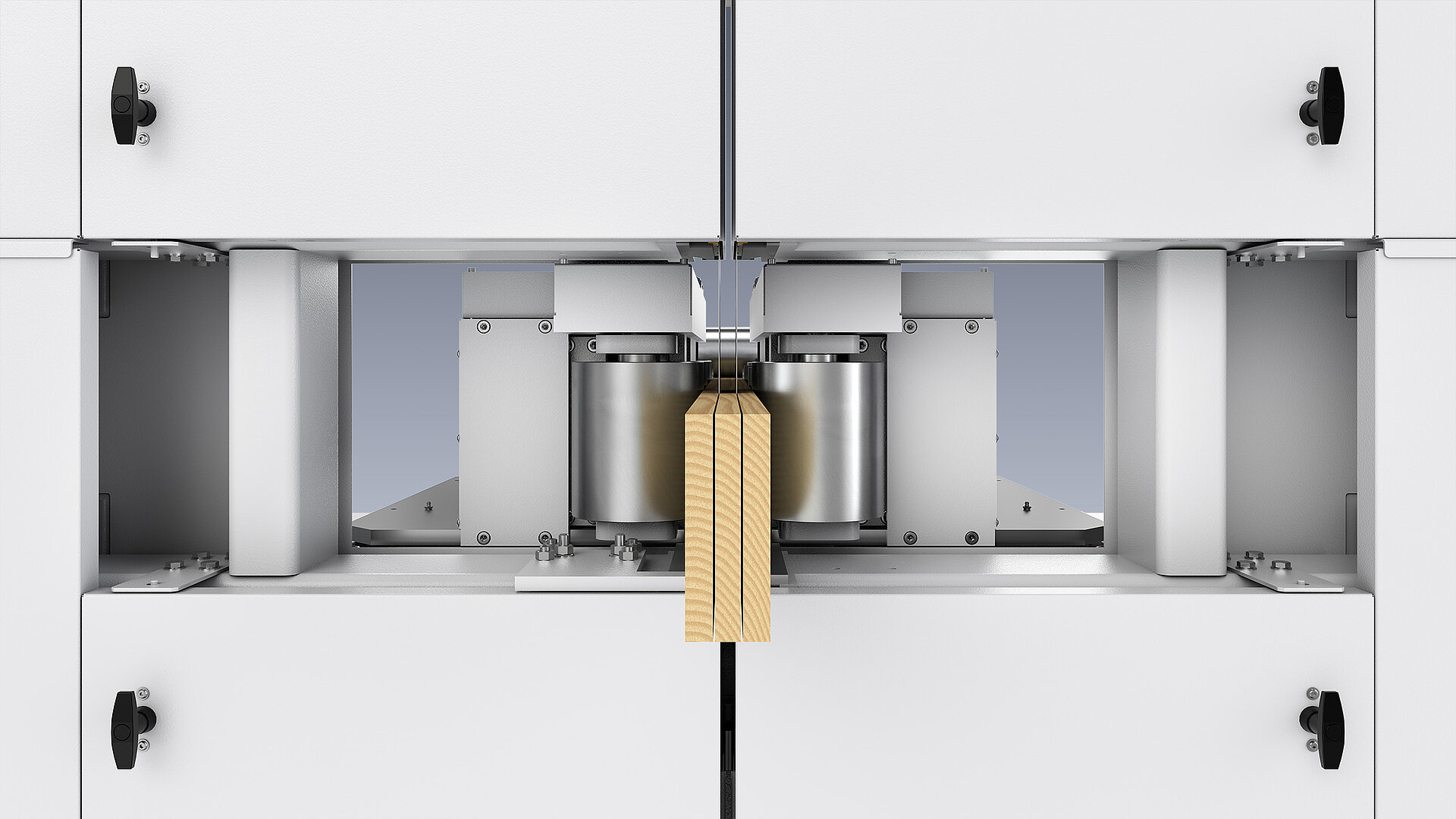

PowerSplit 1250

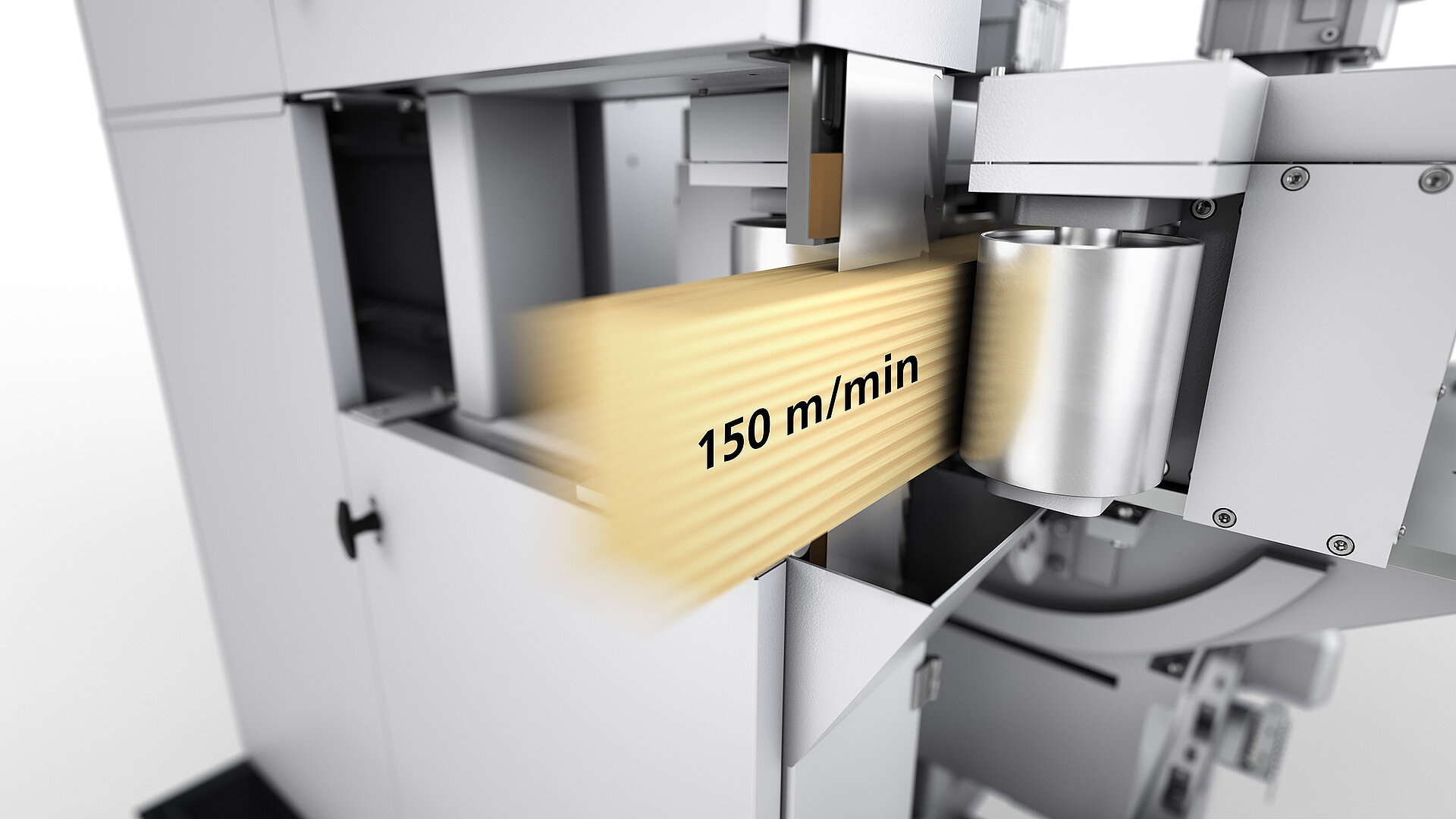

The high-performance band resaw for maximum productivity in continuous operation Back to previous page150 m/min feed speed, minimum kerf, perfect quality, short setup times and smooth throughfeed are an unbeatable combination. The “Single” power package guarantees reliable and powerful production with maximum safety for the operator. The freely positionable control panel offers further advantages - all sawing functions can be easily adjusted and up to 30 cutting dimensions can be stored.

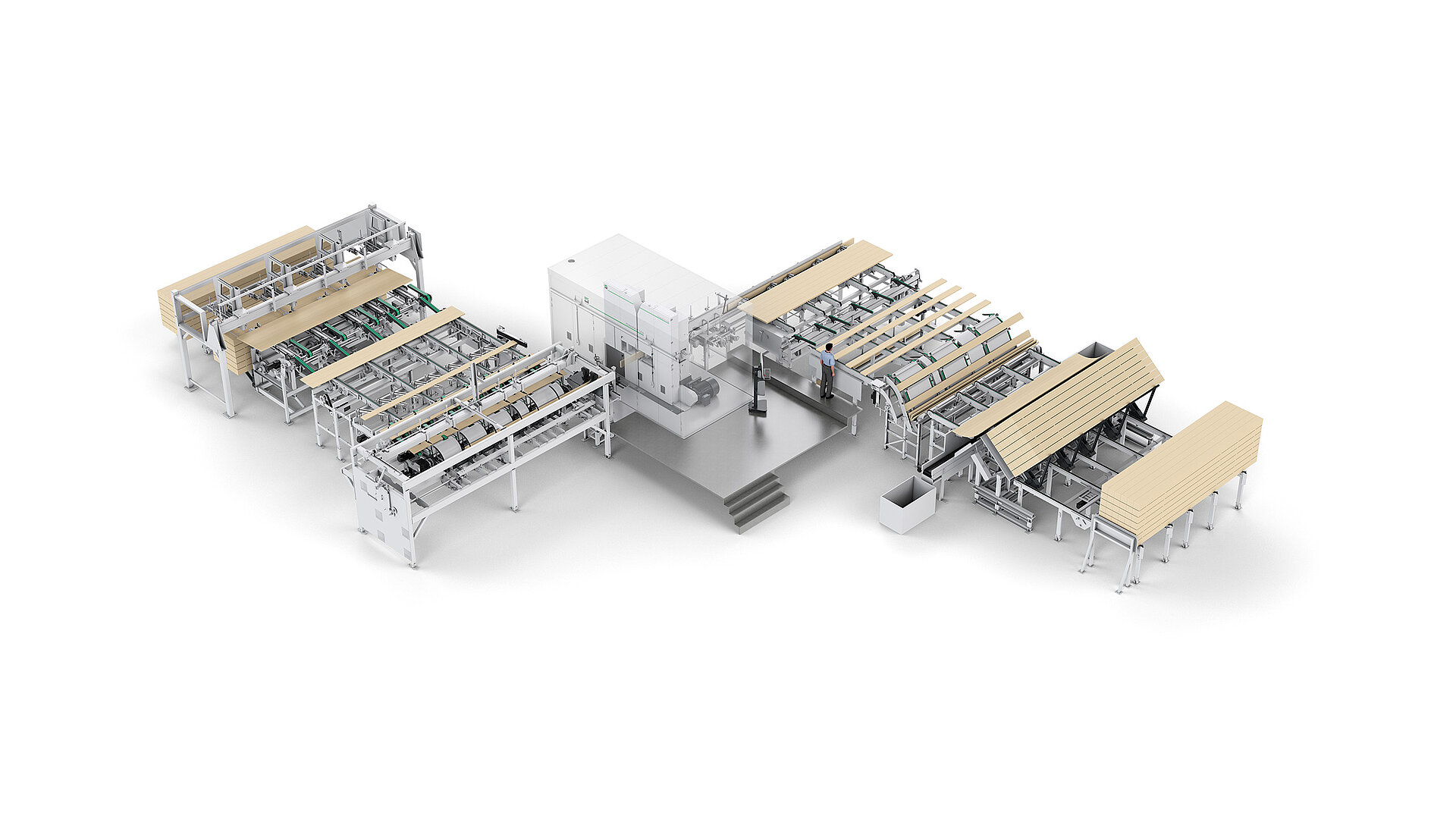

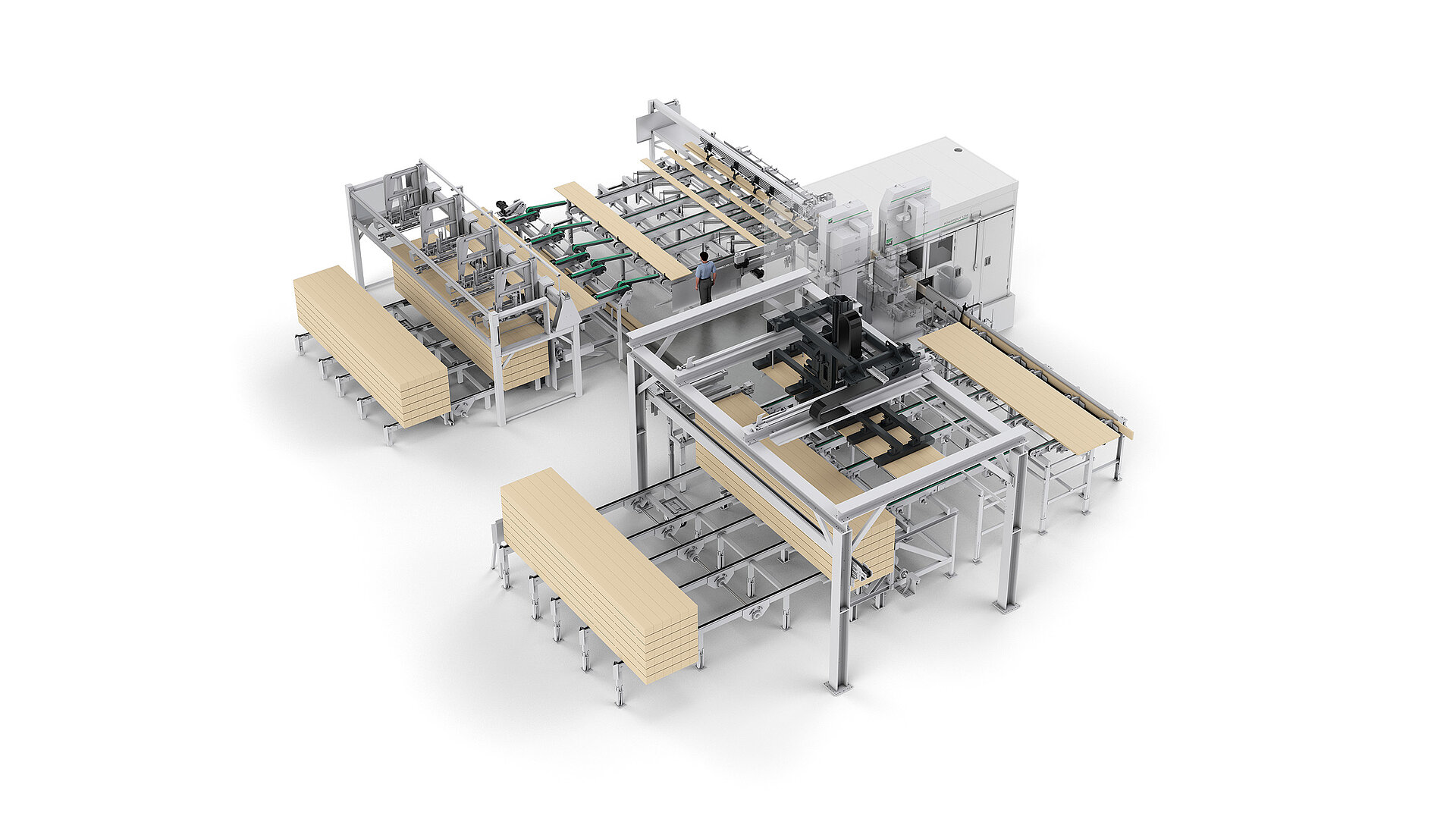

- Optimum material yield thanks to the center cut device

- Freely selectable stop side provides flexibility

- Minimum setup times thanks to sawing units that can be positioned on both sides (TWIN)

- High dimensional accuracy thanks to precise band saw blade guidance and monitoring

- Efficient and powerful motors for the high-performance sector

The PowerSplit 1250 provides

The intuitive controls on the large 21.5" display are easy to understand and actively support the operator. In addition, ten languages are stored in the controller by default, and they can be changed immediately with just one click. All operating functions with the stored cutting dimensions can be saved individually for each customer and processed fully automatically. The control panel itself is freely positionable.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/9/csm_OptiCut_450_Experience_aa982fa2c2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/6/csm_Hydromat_4400_Header_95d7d56df5.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/f/csm_2023-03_Conturex_L_Header_4cf664bc9e.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/c/csm_ProfiPress_C_Experience_58a67838f8.png)