![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/6/csm_Hydromat_4400_Header_95d7d56df5.png)

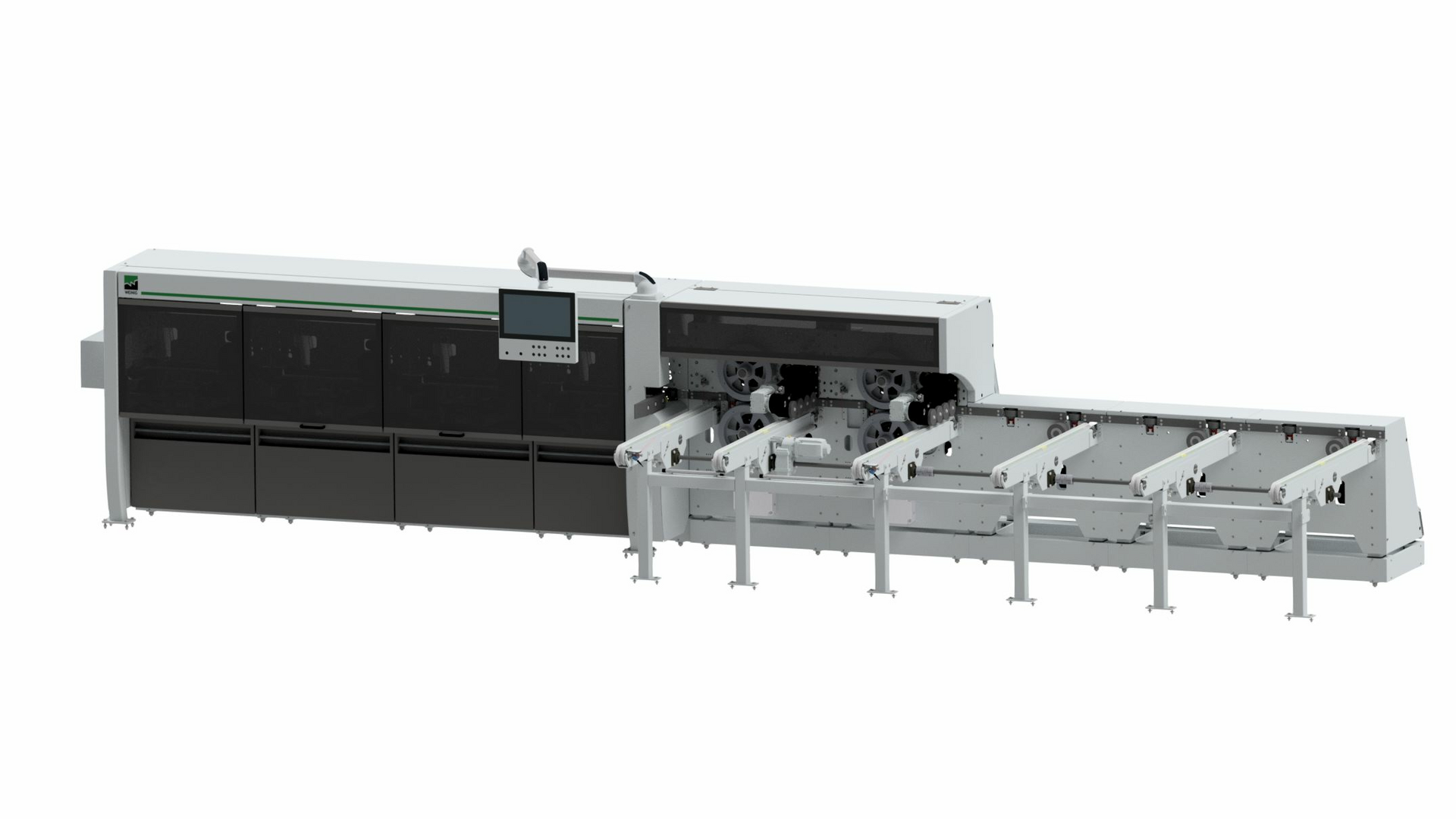

Hydromat 4400

The powerhouse for maximum productivity Back to previous pageThe Hydromat 4400 combines all requirements for a high-speed machine: massive design, powerful infeed unit and excellent performance potential. The new optimized Hydromat 4400 is robust, powerful and reliable for feed rates from 150 - 400 m/min. The modular design allows flexible equipment configurations and spindle arrangements for individual applications. The areas of application range, for example, from rough planing with only a few spindles and low demands on surface quality to the production of diverse profiled elements with a correspondingly high number of spindles and high flexibility.

- High performance potential thanks to a robust and powerful feed unit

- Smooth running due to secure and smooth workpiece guidance

- Easy maintenance design

- Simple operation via the clearly arranged central dashboard in the control system

- Connection to the high-level central system control

The Hydromat 4400 provides

Intuitive machine operation

Automatic dimension changes

Comfortable setup

Predictive maintenance

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/7/csm_PowerSplit_1250_Header_0605d09b04.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/9/csm_OptiCut_450_Experience_aa982fa2c2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/f/csm_2023-03_Conturex_L_Header_4cf664bc9e.png)