WEINIG Software Solutions

Digitization with the WEINIG Group Back to previous pageThere is a clear trend towards software solutions in the woodworking industry. They enable wood processing companies to gain efficiency in their production processes, minimize errors and increase their overall competitiveness. Software solutions are used, for example, to optimize machine controls, automate material inventories and production processes, and facilitate order planning.

APP SUITE

With the functions of the WEINIG App Suite, you can monitor your machines in real time, discover hidden potential and raise your production to a new level. The individual push notifications keep you well informed at all times and in all places. You can make better decisions with the help of the evaluations and through transparency. The App Suite enables the ideal networking of all WEINIG machines. In this way, we provide every customer/user with the right equipment for their path to digitalisation - regardless of whether they are a traditional craft business or an industrial company.

- Current orders

- Operating data

- Service intervals

- Downtimes

CONTROL SUITE

The WEINIG Control Suite is a reliable, effective and efficient solution for system control. As a central system control software, it controls your machines and the processing stations of a system in a straightforward and automated way. It enables effective automation, monitoring and control of production in real time. The one-time data entry at a central location minimizes potential sources of error, as the data is automatically forwarded to the various machines and stations.

At the same time, the system creates a fully digitized process from order entry to order completion notification. The MES also enables the seamless transfer of orders from an ERP system. Another advantage of the software is that systems can be operated with fewer employees. This leads to cost savings.

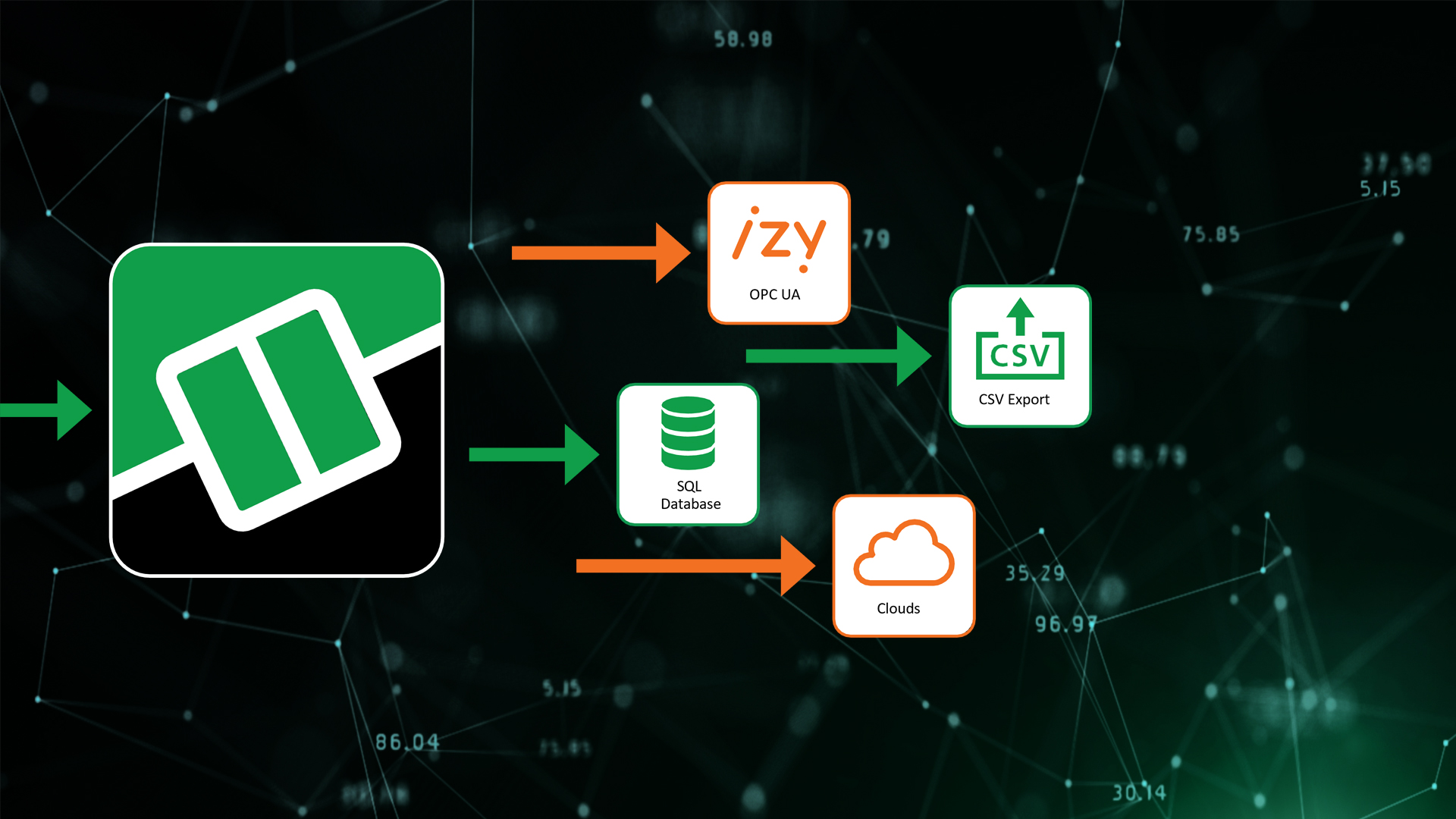

VIACONNECTOR EDGE

With viaConnector Edge, machine data is effortlessly exported from WEINIG / HOLZ-HER machines to an individual target system defined by the customer. Possible targets are, for example, a local drive for saving to a CSV file or an SQL database. No Internet connection is required to use this solution if a local network is available.

In addition, the raw machine data can be processed independently in a third-party system, which saves time and effort. The viaConnector Edge solution thus provides an efficient and user-friendly way to transfer and process machine data quickly and easily.

VIABOX

The viaBox is a mini PC specially designed for the connection between machines and software solutions. With the viaBox, data is transmitted to the WEINIG App Suite or Control Suite in real time. Real-time data visualization is shown on a separate monitor or on the integrated display, making it easier for you to monitor machine processes. The viaBox also makes it easier to connect machines without PC control to the digital world. It can be installed in or at the control cabinet or at another location near the machine. The viaBox also supports the connection of third-party machines to WEINIG software solutions via the OPC UA standard. With all these benefits, the viaBox is a valuable addition to any modern manufacturing environment.